A small plastic bag making machine is typically designed for thin, flexible films—PE/PP rolls, light tension, and high-speed sealing/cutting cycles. But in many factories, management wants more from existing assets: “Can we retr...

VIEW MORE

In many regions, the most profitable bag businesses are not the largest—often they are the most flexible. A small plastic bag making machine can be a smart choice for niche markets where customers demand short runs, frequent size chan...

VIEW MORE

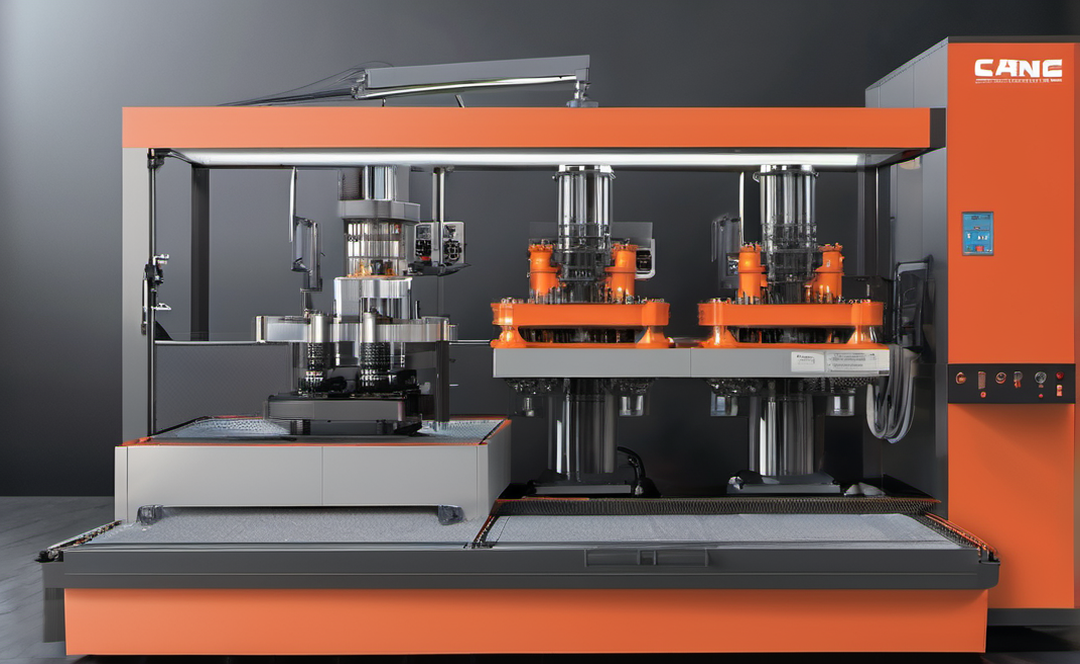

PVC products—stationery bags, cosmetic pouches, tool packaging, and protective covers—often rely on high-frequency (HF) welding to achieve clean, strong seams. Compared with thermal sealing, HF welding can offer excellent appear...

VIEW MORE

HDPE bags are widely used for retail, industrial liners, and heavy-duty packaging because HDPE can deliver excellent stiffness and tensile performance at low thickness. But producing high-strength HDPE bags consistently requires more than a...

VIEW MORE

A pinch bottom bag making machine is a high-value asset in packaging plants because it forms stable bottoms and consistent bag shape—but it also contains critical stations that can become failure points if maintenance is not standardi...

VIEW MORE

As packaging shifts toward higher perceived value—better shelf presence, stronger load performance, and premium branding—many factories are evaluating whether to move beyond standard flat bags. A modern box bag making machine (i...

VIEW MORE

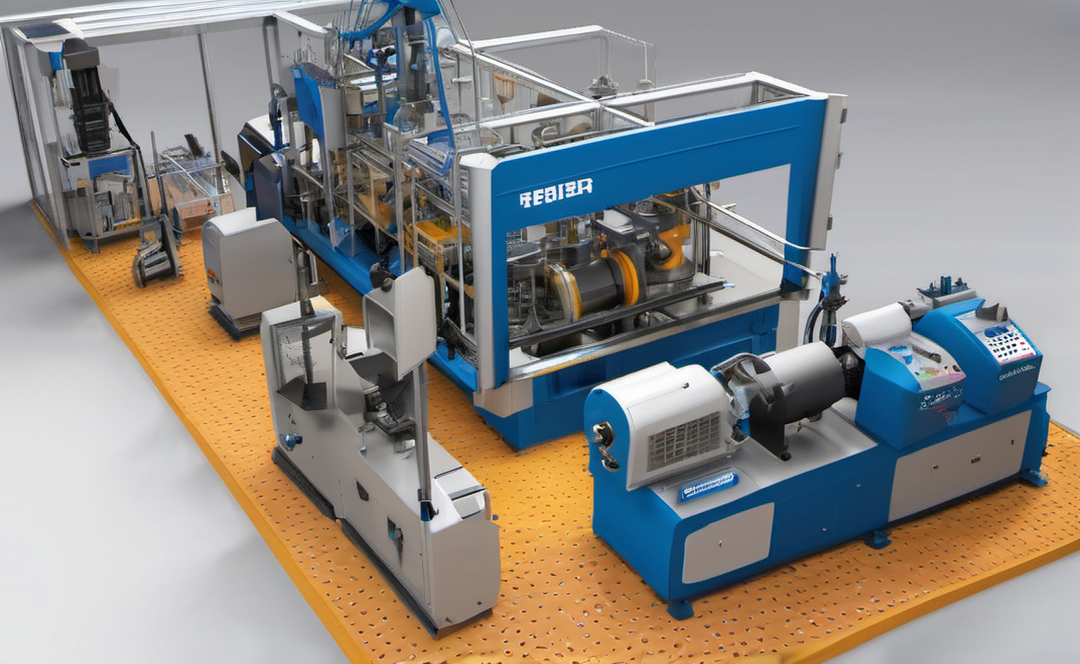

Modern bag factories are moving from “operator-driven lines” to data-driven production. In this shift, the fully automatic plastic bag making machine becomes a core node in the smart factory: it generates production data, q...

VIEW MORE

Buyers searching for a plastic bag making machine price often find wide price ranges and confusing specifications. The reason is simple: “plastic bag machine” can mean very different automation levels, speeds, and bag types&mdas...

VIEW MORE

Many buyers in healthcare-related supply chains ask a new question: can we produce biodegradable packaging while maintaining medical-grade quality systems? If your customers require controlled production, traceability, and documented procedures, you ...

VIEW MORE

When buyers compare a non woven bag making machine price, the cheapest option often looks attractive—until real production costs reveal themselves: labor, downtime, inconsistent welding, and limited upgrade paths. This deep analysis explai...

VIEW MORE

Running a blown film line is a balance between materials, airflow, temperature, and tension. When things go wrong, the symptoms—unstable bubble, thickness drift, wrinkles, haze, gels, or weak seals—often appear suddenly and can destroy ou...

VIEW MORE

In sheet production, “stable output” is not enough. Real profit comes from uniform thickness, consistent appearance, and low scrap rate—especially when customers demand tight tolerances. Many thickness and surface problems orig...

VIEW MORE