High-speed wicket bags are widely used for food, retail, and industrial packaging because they can be automatically loaded onto wicket pins for fast filling. But producing stable wicket stacks at high speed requires more than a basic bag former—it needs precise mechanical design and tension control.

This article explains how a poly bag manufacturing machine (also searched as a poly bag machine) achieves accurate wicket stacking, and what to check when evaluating poly bag making machine price.

1) What is a wicket bag and why stacking quality matters

Wicket bags are typically supplied in stacks with holes punched at the top. Packaging lines depend on:

- Uniform stack alignment

- Consistent hole position

- Stable bag length and seal quality

Poor stacking causes:

- Feeding jams on customer lines

- Higher rejection rates

- Complaints even when seals look fine

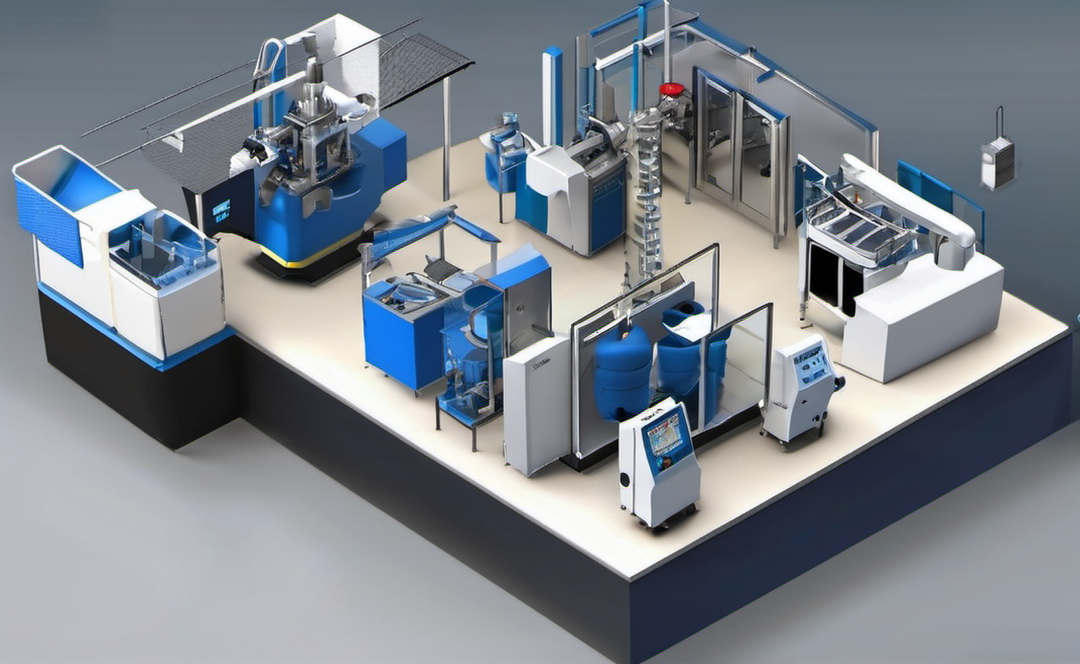

2) Core mechanical principle of wicket stacking

A high-speed wicket system coordinates:

- Film feeding and registration

- Sealing and cutting timing

- Punching position control

- Counting and stacking onto pins or fixtures

The goal is repeatable placement with minimal vibration and minimal film stretch variation.

3) Tension control: the “hidden” factor behind stable bags

Tension instability leads to:

- Length drift

- Seal misalignment

- Hole offset

- Curling and poor stack squareness

Good machines combine:

- Dancer rollers / load-cell feedback (depending on design)

- Servo-driven pull systems

- Closed-loop control parameters for different film thicknesses

If your target is thin film at high speed, tension control becomes even more critical.

4) Key modules to evaluate on a high-speed poly bag machine

Feeding and guiding

- EPC/web guiding to keep edges aligned

- Stable unwinding shafts and braking control

Sealing unit

- Temperature stability and pressure uniformity

- Fast cycle time without overheating

Punching unit

- Accurate servo timing

- Clean scrap removal design

Stacking and counting

- Anti-static measures

- Reliable counting sensors

- Stable pin/fixture movement with low vibration

5) How to protect thin film stability at high speed

Practical recommendations:

- Use servo pulling with proper acceleration curves

- Add web guiding and anti-static devices

- Ensure sealing bar flatness and pressure balance

- Maintain sharp cutting blades and correct anvil alignment

6) Poly bag machine price: what you are really paying for

Buyers often compare:

- poly bag machine price

- poly bag making machine price

- polypropylene bags manufacturing machine

- poly bag manufacturing machine

Cost differences usually reflect:

- Servo level (single servo vs multi-servo)

- Tension control system design

- Wicket stacking accuracy and maximum stable speed

- Automation level and safety guarding

- Electrical brands and long-term spare parts availability

7) Conclusion

For wicket bags, stacking quality is a direct result of mechanical timing precision and tension control—not just nominal speed. When selecting a poly bag manufacturing machine, evaluate the entire system: feeding, sealing, punching, counting, and stacking stability.

If you share your bag size range, film thickness, target speed, and wicket standard, we can recommend a suitable model and provide a detailed configuration-based quotation.

Table of Contents

- 1) What is a wicket bag and why stacking quality matters

- 2) Core mechanical principle of wicket stacking

- 3) Tension control: the “hidden” factor behind stable bags

- 4) Key modules to evaluate on a high-speed poly bag machine

- 5) How to protect thin film stability at high speed

- 6) Poly bag machine price: what you are really paying for

- 7) Conclusion