Selecting the right process is the key decision when buying a non woven making machine. The two most common joining methods for non woven bags are ultrasonic bonding and needle stitching. Each has different performance in strength, appearance, speed, and operating cost.

This guide compares both technologies and explains why ultrasonic bonding is often preferred when buyers want consistent quality and higher automation on an automatic non woven bag making machine.

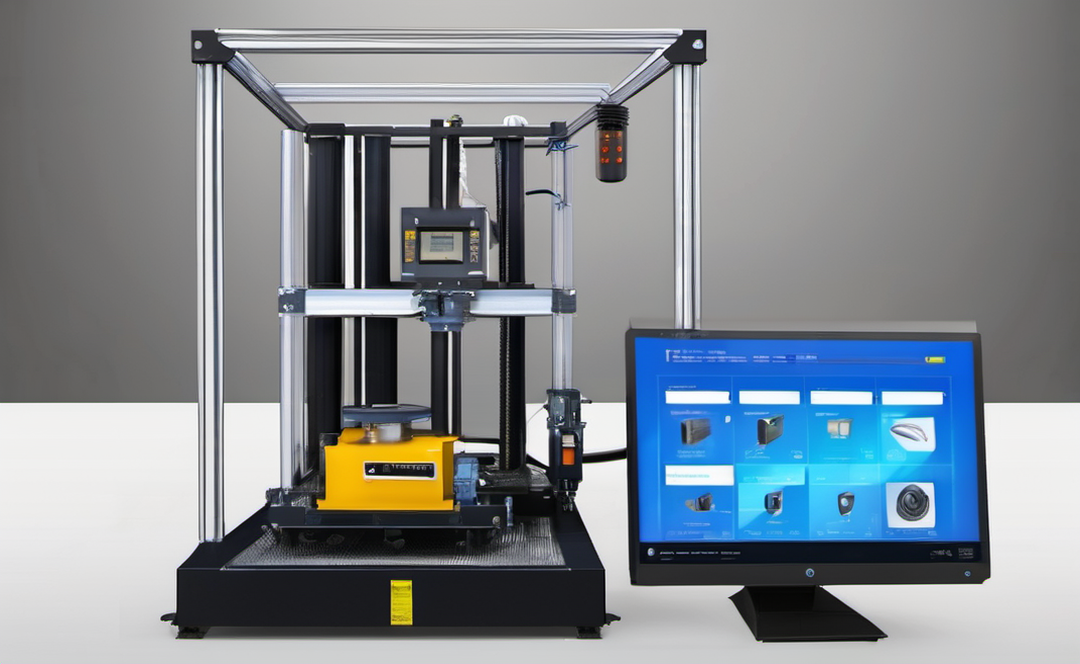

1) How ultrasonic bonding works on non woven bags

Ultrasonic systems use high-frequency vibration to generate localized heat through friction. Thermoplastic fibers melt and fuse, creating:

- Clean edges

- Sealed seams

- Decorative embossing patterns (depending on wheel design)

Ultrasonic bonding is especially suitable for PP non woven fabrics commonly used in shopping bags and promotional bags.

2) How needle stitching works

Needle stitching uses thread to join panels. It is:

- Highly familiar to many factories

- Flexible for certain structures

- Potentially stronger for some thick/complex designs

However, stitching adds consumables (thread), more maintenance, and sometimes less consistent seam appearance.

3) Strength and seam consistency

Ultrasonic bonding

Pros:

- Consistent seam width and finish in stable material conditions

- No needle holes (can reduce tearing around perforations)

Considerations:

- Sensitive to fabric GSM, resin composition, and lamination layers

- Needs correct horn/wheel selection and stable pressure settings

Needle stitching

Pros:

- Works across a wider range of materials and thickness

- Strength can be tuned via stitch density and thread type

Considerations:

- Needle holes can weaken certain fabrics

- Seam quality depends more on operator skill and machine condition

4) Speed and cleanliness in mass production

Ultrasonic bonding is often chosen for high-volume production because it can deliver:

- Higher continuous speed

- Less dust/thread management

- Cleaner lines and better visual finish

Needle stitching often requires:

- More frequent stops (thread breaks, tension adjustments)

- More manual involvement

5) Appearance and branding effects

For retail and promotional bags, aesthetics matter:

- Ultrasonic seams look “sealed” and premium

- Stitching is visible and may look less modern, though some buyers view it as “strong”

6) Which technology should you choose?

Recommended approach:

- If you focus on standard bag designs, high output, clean seams → ultrasonic

- If you frequently change materials, need特殊结构 reinforcement, or want maximum flexibility → stitching (or hybrid designs)

7) What impacts the non woven bag making machine price?

Common search terms include:

- non woven manufacturing machine

- non woven bag manufacturing machine price

- non woven fabric bag making machine price

Price differences usually come from:

- Ultrasonic generator power and stability

- Horn/wheel material and lifespan

- Servo control level (feeding, cutting, sealing)

- Auto handle attachment systems

- Stacking/counting automation and safety guarding

8) Conclusion

Ultrasonic bonding is often the best choice for factories aiming for high speed, clean seams, and consistent output on an automatic non woven bag making machine. Stitching remains useful for flexible material ranges and certain reinforced structures.

If you tell us your bag type (D-cut, box bag, loop handle, etc.), fabric GSM range, and target speed, we can recommend the best configuration and provide an accurate quotation.

Table of Contents

- 1) How ultrasonic bonding works on non woven bags

- 2) How needle stitching works

- 3) Strength and seam consistency

- 4) Speed and cleanliness in mass production

- 5) Appearance and branding effects

- 6) Which technology should you choose?

- 7) What impacts the non woven bag making machine price?

- 8) Conclusion